We take our design process very seriously, from the original sketch down to the last bolt in the production line, we expect to deliver on our promise of creating the most advanced electric scooters in the world.

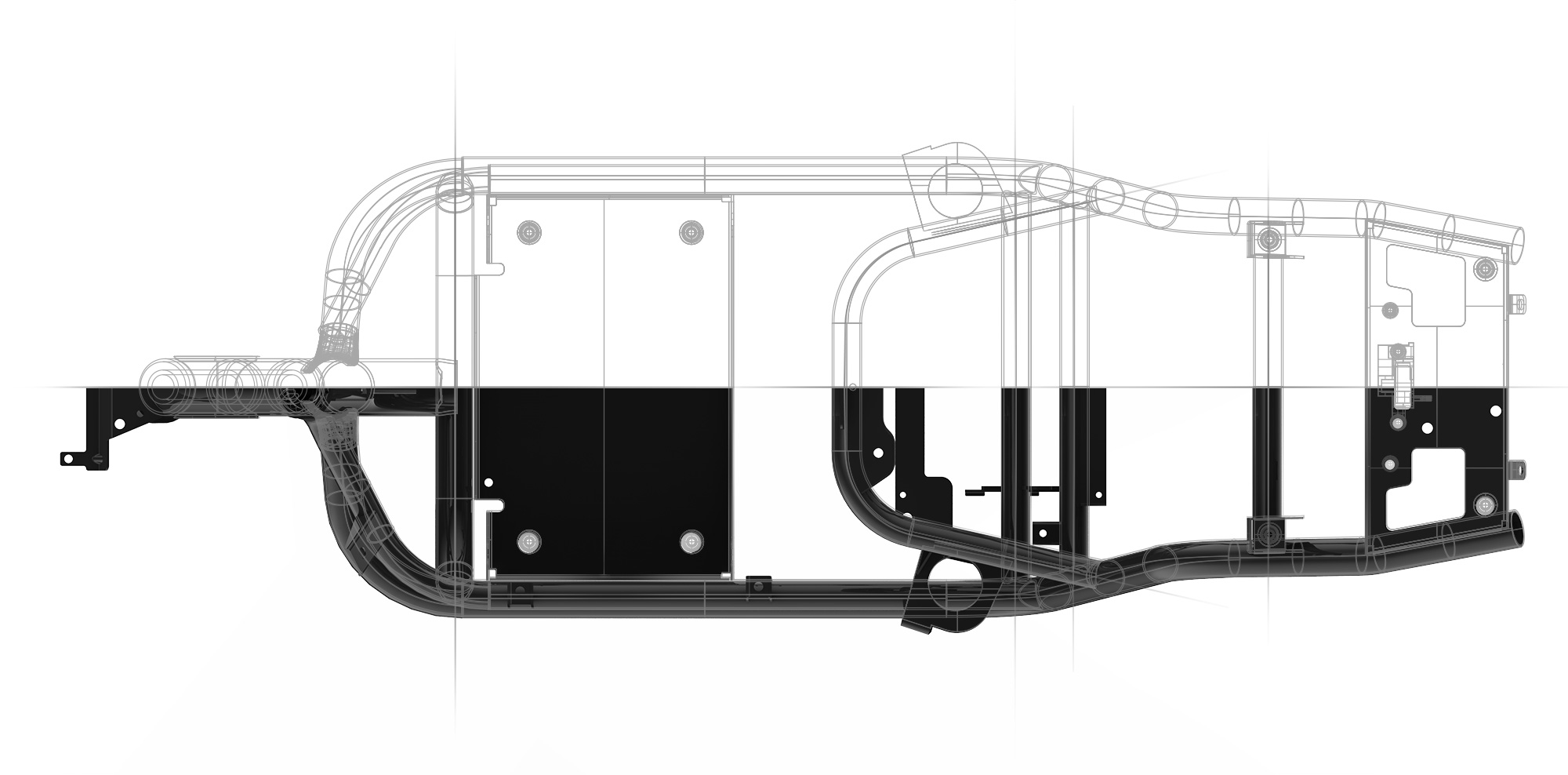

We have collaborated with the same world-class supplier that builds frames for many leading international motorcycle brands. Our welding process utilizes a fully robotic arm to ensure the highest level of consistency for each and every frame in our NQi-Seriess.

The NQi-Series frame utilizes an ultra high-strength alloy steel that is the foundation for the entire vehicle.

Beyond the robotic-arm assisted welding, the NQi-Series frame and chasis undergo a number of processes to increase strength and long term durability. We use a painting technology known as electrophoresis that ensures consistency while simultaneously creating an additional layer between the steel-alloy and external elements. The surface goes through an additional process known as phosphating and electrostatic spraying that builds the final barrier between the frame and corrosive elements.

We use a Titanium-alloy to build our swing-arm. Titanium has allowed us to increase the tensile and twisting strength by nearly 50% while simultaneously reducing the NQi-Series curb weight.

Employing an ultra-high temperature casting procedure, our Aluminum and Titanium alloy has allowed us to build a swingarm that is stronger than either metal on their own.

Our post-processing techniques combined with enhanced CNC truing and polishing have allowed us to elevate the swingarm to a new level of aesthetic practicality without sacrificing performance.

We have equipped the NQi-Series with front and rear dual hydraulic shock-absorbers.

Combine this with our Aluminum-Titanium swing arm, and we have engineered a riding experience that is pleasant no matter what the road throws at you.

When we designed the suspension and shock absorbers we wanted to keep the ultimate riding experience of the open-road while paying close attention to the demands of rough urban streets. We utilize a pre-compression technology that reduces the vibrations of the road while still allowing the rider to feel firmly connected to the street below the wheels.

The NQi-Series' patented body design employs over 200 sets of molds

and two years of development.

The UV resistant painting process is essential to keeping your NQi-Series looking as good as the day you bought it.

Layers and layers of paint, polish, primer, gloss, and a finishing coat give the final glean that lasts far beyond the first moment you ride the NQi-Series down the street.

We employ a unique tread design that adds a layer of safety when driving on either wet or dry roadways. The central and radial channels enable a naturally straighter ride while simultaneously helping to deflect and push water away from the tires during heavy rains.

All of the onboard components susceptible to water and dust have been fitted with IP65* grade protective gear. Components like the battery pack, motor controller, power converter, head lamp, dash board, and many others have been equipped with protectants so you can be certain that you are safe while on the road. Even our electronic brakes are performance rated up to 230mm of water.

*Dustproof Grade 6: Fully resistant to dust.

Waterproof grade 5: No lasting damage is caused when splashed or briefly submerged in water.